In the world of fluid handling, selecting the appropriate fluid fittings can significantly influence the efficiency and safety of your project. As industry expert Dr. Emily Thompson, a recognized authority in fluid mechanics, aptly puts it, "The right fluid fittings not only ensure a leak-free system but also enhance the overall performance of fluid applications." This statement underscores the critical role that fluid fittings play in various industrial applications, from manufacturing to automotive and beyond.

As we navigate the complexities of choosing the best components for your fluid system, this comprehensive guide on "How to Choose the Right Fluid Fittings for Your Project" will provide you with the essential insights and considerations necessary for making informed decisions. By understanding the types of fluid fittings available, their materials, and the specific requirements of your application, you can optimize your fluid management strategy effectively. Whether you're working on a new installation or upgrading existing systems, the right fluid fittings are paramount to achieving seamless performance and durability in your operations.

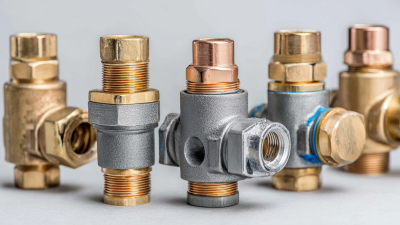

Fluid fittings are essential components in the management of fluids within various applications, ranging from industrial machinery to plumbing systems. Understanding the different types of fluid fittings is crucial for selecting the right one for your project. Common types include valves, hoses, couplings, and adapters, each serving a specific purpose. Valves control the flow of fluids, while hoses transport them. Couplings allow for quick connections and disconnections, and adapters facilitate compatibility between different sizes or types of fittings.

Fluid fittings are essential components in the management of fluids within various applications, ranging from industrial machinery to plumbing systems. Understanding the different types of fluid fittings is crucial for selecting the right one for your project. Common types include valves, hoses, couplings, and adapters, each serving a specific purpose. Valves control the flow of fluids, while hoses transport them. Couplings allow for quick connections and disconnections, and adapters facilitate compatibility between different sizes or types of fittings.

When considering the uses of fluid fittings, it's important to look at materials and design. For instance, metal fittings are often preferred in high-pressure applications due to their durability, while plastic fittings are lighter and corrosion-resistant, making them suitable for chemical applications. Additionally, variations such as threaded, push-fit, and welded fittings cater to unique installation requirements and space constraints. By understanding these distinctions, you can make informed choices that enhance the efficiency and safety of your fluid systems.

When selecting fluid fittings for various applications, it’s essential to understand the specific requirements of your project. According to a report from the Fluid Power and Controls Industry Association, approximately 70% of hydraulic system failures are attributed to improper fittings. Therefore, ensuring the right type, size, and material of the fittings is critical. For example, when dealing with high-pressure applications, fittings made from stainless steel or special alloys are recommended due to their superior strength and resistance to corrosion.

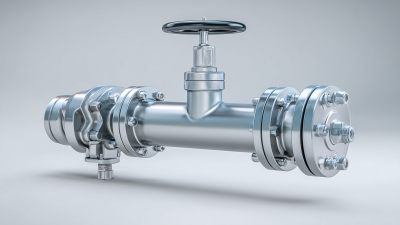

Moreover, the compatibility of the fitting with the fluid being transported cannot be overlooked. A study by the International Fluid Power Society highlights that improper material selection can lead to chemical reactions, compromising performance and safety. For applications involving aggressive fluids or high temperatures, selecting fittings that meet industry-specific standards, such as SAE J514 for hydraulic applications, is crucial. Additionally, factors like connection type—be it threaded, welded, or quick-connect—must also align with the project’s operational requirements to ensure optimal functionality and leak prevention.

When choosing fluid fittings for your project, the material of the fittings plays a crucial role in determining their overall performance and longevity. Common materials used for fluid fittings include stainless steel, brass, plastic, and more specialized alloys. Each material has distinct properties that can significantly affect reliability, resistance to corrosion, temperature tolerance, and compatibility with various fluids. For example, stainless steel fittings offer exceptional corrosion resistance and strength, making them ideal for harsh environments and high-pressure applications. On the other hand, plastic fittings are lightweight and resistant to chemical corrosion, making them suitable for less demanding applications where cost is a primary concern.

The impact of material choice extends beyond performance characteristics; it also influences maintenance needs and long-term operational costs. Fittings made from durable materials typically require less frequent replacements, reducing downtime and maintenance expenditures. Additionally, understanding the fluid's characteristics—such as pH levels, viscosity, and temperature—is essential for selecting the right material. By thoroughly assessing the operational conditions and material properties, you can ensure that the fluid fittings selected will perform optimally and enhance the efficiency of your project.

When selecting fluid fittings for your project, avoiding common pitfalls can save you time and resources. One major mistake is underestimating the compatibility of materials. Not all fittings are suitable for every type of fluid, which can lead to leaks or corrosion over time. It's essential to consider the fluid's chemical properties and the fitting materials to ensure long-lasting performance.

Another common error is neglecting to consider pressure and temperature ratings. Every fitting comes with specific ratings that indicate its operational limits. Choosing a fitting without verifying these ratings can result in catastrophic failures. Additionally, many project managers overlook the importance of proper sizing. Using fittings that do not match the diameter of the hoses or pipes can restrict flow or create additional stress on the system, potentially leading to premature failure. By being aware of these pitfalls, you can make informed choices that bolster the reliability and efficiency of your fluid systems.

When it comes to installing and maintaining fluid fittings, adherence to best practices is essential for ensuring optimal system performance and longevity. According to a report by the Fluid Power Society, improperly installed fittings can lead to leaks that account for about 20% of hydraulic system failures. To prevent this, it is crucial to follow manufacturer specifications regarding torque settings and connection types. Standard hydraulic fittings should be inspected for thread damage and corrosion before installation to ensure a secure and leak-free assembly.

Regular maintenance and inspection of fluid fittings are equally important. The National Fluid Power Association recommends a routine check every six months, focusing on connection tightness and signs of wear or damage. Studies indicate that proactive maintenance can reduce downtime and improve system efficiency by up to 30%. Utilizing high-quality materials and adhering to industry standards during both installation and maintenance can significantly enhance the reliability and performance of fluid fitting systems in various applications.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.